Redefining Energy Storage and Power Conversion

The Chemical Evolution of Battery Cells

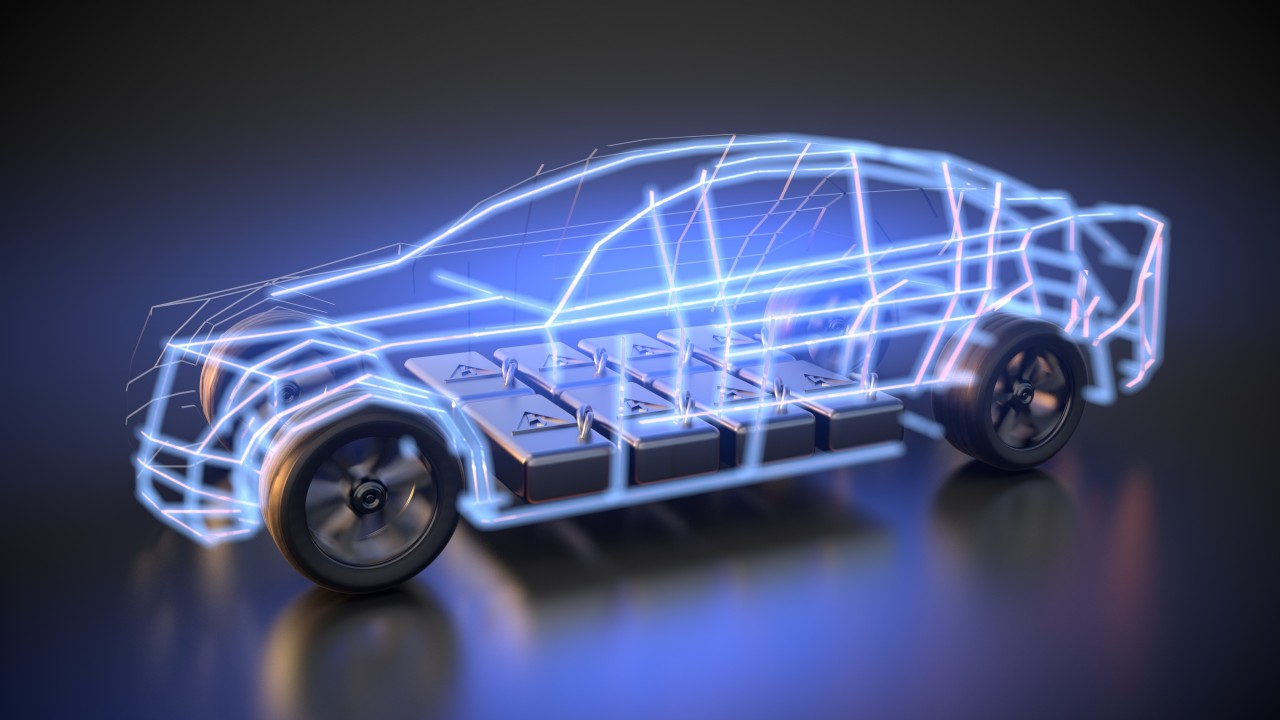

The battery remains the definitive component of any electric vehicle, yet the technology driving it extends far beyond simple energy storage. To tackle the dual challenges of increasing energy density and reducing manufacturing costs, the industry is moving toward a vertically integrated supply chain that scrutinizes every gram of material used. A significant focus is currently placed on the internal architecture of the cells themselves, particularly the development of next-generation active materials.

Innovators are moving past traditional chemistries to explore high-capacity solutions. For instance, the integration of lithium metal composite anodes represents a major leap forward, offering the potential to store significantly more energy in a smaller footprint compared to conventional graphite anodes. Simultaneously, engineers are refining nano structured cathodes to improve charge transfer rates and structural stability during repeated cycling. Beyond lithium, sodium-ion technologies are transitioning from laboratory experiments to practical applications, offering a strategic hedge against resource scarcity. Furthermore, the concept of the circular economy is becoming central to battery design. By engineering cells that are easier to recycle and utilizing reclaimed materials without sacrificing performance, manufacturers are ensuring that the path to zero emissions remains environmentally sustainable from production to end-of-life.

Managing Heat in Power Electronics

While the battery stores the energy, the power electronics system is responsible for managing and converting that energy to drive the motor. This conversion process generates immense heat, making thermal management a critical factor in vehicle performance and reliability. In the realm of inverters and power modules, standard soldering techniques are increasingly being replaced by advanced interface materials that can withstand higher operational temperatures and mechanical stress.

One of the most promising developments is the use of pressure-sintered copper pastes. Unlike traditional solders, these materials provide superior thermal and electrical conductivity, essential for handling the high currents of modern EV powertrains. This evolution extends to the use of specialized conductive adhesives that facilitate robust electrical connections while simultaneously dissipating heat. These advanced bonding agents are often used in conjunction with ceramic-copper substrates, which offer an ideal balance of electrical insulation and thermal conductivity. By efficiently transferring heat away from sensitive semiconductors, these materials allow for more compact, higher-output inverter designs. This reliability is crucial not only for vehicle longevity but also for enabling rapid charging capabilities, which place significant thermal loads on the vehicle's electrical infrastructure.

| Feature | Sintered Copper Paste | Traditional Solder | Conductive Adhesives |

|---|---|---|---|

| Thermal Conductivity | Extremely High | Moderate | Variable (High for specific grades) |

| Operating Temp | High (>300°C capability) | Low to Medium | Medium |

| Mechanical Stress | Excellent fatigue resistance | Prone to cracking over time | Flexible, absorbs vibration |

| Primary Use Case | Power module die attachment | General electronics | Flexible circuits & component bonding |

| Processing | Requires pressure & heat | Simple reflow process | Curing (Heat or UV) |

Mastering Thermal Dynamics and Surface Tech

Advanced Resins for Extreme Temperatures

As electric drivetrains become more powerful, the thermal demands placed on surrounding components escalate. The industry is witnessing a shift away from standard plastics toward high temperature polymers capable of surviving environments exceeding 300 degrees Celsius. These are not merely heat-resistant shells; they are engineered to be thermally conductive while maintaining electrical insulation—a paradoxical set of properties that is vital for EV safety.

Chemical manufacturers are achieving this by embedding specific fillers, such as boron nitride, into the polymer matrix. By aligning these nano-fillers and optimizing their surface treatment, the resulting composite material can "guide" heat away from hotspots much like a metal heatsink, but with the light weight and formability of plastic. These materials are finding their way into battery enclosures, busbar holders, and motor housings. Additionally, lightweight foam materials, originally born from aerospace research, are being adapted as fire-retardant barriers. These foams not only provide thermal insulation to prevent heat propagation between battery cells but also suppress smoke generation in the event of a thermal runaway, directly enhancing passenger safety.

Surface Engineering for Longevity

Efficiency in an electric vehicle is often a war against friction. Even the smallest mechanical resistance in the drivetrain translates to lost range. To combat this, surface engineering has moved to the forefront of component design. Engineers are applying advanced thin-film coatings, such as Diamond-Like Carbon (DLC), to moving parts within the reduction gear and cooling pumps. These coatings dramatically reduce the coefficient of friction, ensuring that energy is used for propulsion rather than wasted as heat.

In the electric motor itself, material science is addressing both durability and efficiency. Ceramic coated motors—specifically the insulation on the winding wires and bearings—are becoming essential. These ceramic-based insulation layers prevent electrical discharge and corrosion, which can occur due to the high-frequency switching of modern inverters. Furthermore, the cleanliness of these surfaces prior to assembly is paramount. Techniques like plasma cleaning are employed to prepare surfaces at the nano-level, ensuring that subsequent coatings or bonding agents adhere perfectly. This meticulous attention to surface chemistry ensures that the vehicle operates smoothly and reliably over hundreds of thousands of miles.

Structural Integrity and Passenger Comfort

Lightweighting with Composite Strength

The weight of the battery pack presents a fundamental challenge for EV design: the vehicle must be light enough to maximize range but strong enough to protect the heavy battery and passengers. This has led to the widespread adoption of fiber-reinforced composites. Carbon Fiber Reinforced Plastic (CFRP) and Glass Fiber Reinforced Polymer (GFRP) are replacing steel in key structural areas. These materials offer a superior strength-to-weight ratio, allowing engineers to shave off kilograms without compromising safety.

A prime example of this application is found in reinforced polymer bumpers and crash boxes. These components are designed to absorb impact energy through controlled crushing mechanisms, shielding the chassis and battery from damage. Unlike metals, which require complex stamping and welding, these thermoplastic composites can be molded into intricate shapes, integrating multiple functions into a single part. Recent innovations also include bio-composites derived from marine waste or plant fibers, proving that structural integrity can coexist with environmental responsibility. This "hybrid molding" capability allows for the creation of parts that are not only lighter but also more aerodynamic, further contributing to the vehicle's overall energy efficiency.

| Material Type | Weight Savings | Cost | Strength/Durability | Primary Application |

|---|---|---|---|---|

| High-Strength Steel | Low (Baseline) | Low | Excellent impact resistance | Main chassis frame |

| Aluminum Alloys | Medium | Medium | Good, but fatigue prone | Body panels, suspension |

| CFRP (Carbon Fiber) | High | High | Extreme rigidity | Structural pillars, roofs |

| GFRP/Thermoplastics | High | Low-Medium | High durability, flexible design | Bumpers, battery enclosures |

Silencing the Ride with Smart Materials

One of the most immediate differences drivers notice in an EV is the lack of engine noise. However, this silence unveils a new set of challenges: road noise, wind buffeting, and structural vibrations become much more prominent. To maintain a serene cabin environment, automotive engineers are turning to "smart" damping materials.

The current trend involves Constrained Layer Damping (CLD) systems, where a layer of viscoelastic polymer is sandwiched between structural panels. This setup converts vibrational energy into specific amounts of heat, effectively deadening the resonance of the car body. Unlike heavy rubber mats used in the past, modern damping solutions are often integrated directly into hybrid aluminum-polymer composites. This integration serves a dual purpose: it reinforces the panel for structural rigidity while simultaneously absorbing sound frequencies that human ears find unpleasant. By replacing heavy metal soundproofing with these smart, integrated materials, manufacturers can deliver a library-quiet interior experience that complements the smooth nature of electric propulsion, proving that comfort does not have to come at the expense of vehicle weight.

Q&A

-

What are the benefits of using Ceramic Coated Motors in industrial applications?

Ceramic Coated Motors provide enhanced thermal resistance, reducing the risk of overheating and improving efficiency in high-temperature environments. The ceramic coating also offers protection against corrosion and wear, extending the motor's lifespan and reducing maintenance costs. -

How do High Temperature Polymers contribute to the automotive industry?

High Temperature Polymers are critical in the automotive industry due to their ability to maintain structural integrity and performance at elevated temperatures. They are used in engine components, reducing weight and improving fuel efficiency while withstanding harsh conditions. -

What advantages do Lithium Metal Composite Anodes offer in battery technology?

Lithium Metal Composite Anodes are crucial in advancing battery technology as they provide higher energy density compared to traditional anodes. This results in longer battery life and quicker charging times, making them ideal for applications in electric vehicles and portable electronics. -

In what ways do Nano Structured Cathodes improve battery performance?

Nano Structured Cathodes enhance battery performance by increasing the surface area for electrochemical reactions, leading to faster charge and discharge rates. This technology also improves the overall stability and longevity of batteries, making them more reliable for long-term use. -

Why are Reinforced Polymer Bumpers preferred in modern vehicle design?

Reinforced Polymer Bumpers are favored in modern vehicle design due to their lightweight nature and ability to absorb impact energy efficiently. This results in improved safety for passengers and reduced repair costs after minor collisions, while also contributing to overall vehicle fuel efficiency. -

What role do Conductive Adhesives play in electronic manufacturing?

Conductive Adhesives are essential in electronic manufacturing as they provide reliable electrical connections without the need for soldering. They are used in applications where heat-sensitive components are involved, offering flexibility in design and reducing potential damage from thermal stress.