Redefining the Silhouette: The Art of Seamless Design

The Shift to Sculptural Purity

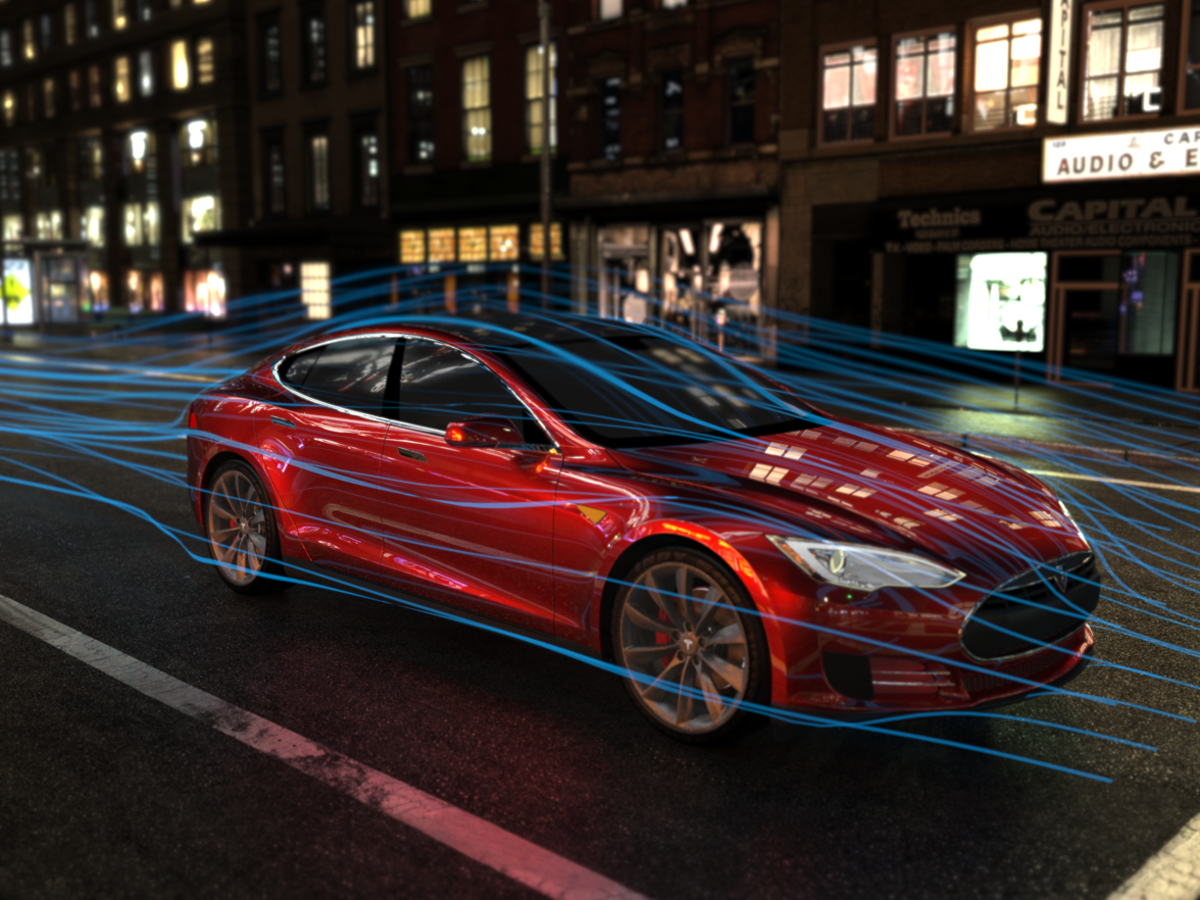

The visual identity of the automobile is undergoing a radical transformation, driven by the unique architecture of electric propulsion. In traditional automotive design, the front of the vehicle was dominated by massive grilles necessary to feed air into hungry combustion engines. However, the electric powertrain liberates designers from this requirement. The "face" of the modern vehicle has evolved into a smooth, unbroken surface that splits the wind rather than swallowing it. This is not merely an aesthetic choice to signal futurism; it is a functional necessity calculated to minimize resistance at every possible point.

Beyond the removal of the grille, the manufacturing process itself has begun to contribute to aerodynamic efficiency. Modern production techniques, such as large-scale casting, allow the rear and front structures of a car to be made from a single piece of metal rather than dozens of welded parts. This reduction in components means fewer panel gaps, fewer seams, and fewer interruptions on the body surface. Every tiny gap on a vehicle’s exterior can create micro-turbulence, disrupting the smooth layer of air passing over the car. By eliminating these imperfections, the vehicle body becomes almost liquid in appearance and function.

Designers are also focusing on flush detailing. Door handles that retract into the bodywork, side mirrors replaced by slender cameras, and windows that sit perfectly flush with the pillars are becoming standard. These features ensure that the air remains attached to the body for as long as possible, reducing the wake left behind the vehicle. The result is a silhouette that looks as though it was carved by the wind itself, achieving a harmony between form and physics that maximizes the energy stored in the battery pack.

The Hidden Revolution Under the Floor

While the smooth curves of the upper body grab the headlines, a perhaps more significant revolution is taking place underneath the vehicle. In internal combustion cars, the undercarriage is a chaotic landscape of exhaust pipes, driveshafts, mufflers, and fuel lines. These protrusions act as obstacles, churning the air and creating significant drag. Electric vehicles, by contrast, utilize a "skateboard" architecture where the battery pack sits flat between the wheels. This structural necessity has gifted aerodynamicists with the ultimate blank canvas: a perfectly flat underbody.

A flat floor allows air to accelerate as it passes beneath the car. According to the principles of fluid dynamics, faster-moving air creates lower pressure. By channeling this air smoothly from the front bumper to the rear diffuser, engineers can create a suction effect that pulls the car down toward the road. This phenomenon essentially mimics the technology found in high-performance racing cars but applies it to family sedans and SUVs. The rear diffuser then acts as an expansion chamber, slowing the air back down as it exits the rear, which helps to minimize the turbulent wake that pulls the car backward.

This management of underbody airflow does more than just help the car slice through the air; it radically transforms the driving experience. By generating downforce without the need for massive wings on the trunk, the vehicle gains stability. The car feels planted and secure, especially at highway speeds, without the penalty of increased drag that usually comes with added grip. It is an invisible optimization that yields tangible benefits in both range and handling confidence.

| Feature Category | Traditional Approach | EV Aerodynamic Approach | Impact on Airflow |

|---|---|---|---|

| Front Fascia | Open grilles for radiator cooling | Smooth, closed-off nose cones | Eliminates high-pressure pockets and internal drag. |

| Undercarriage | Exposed pipes, axles, and uneven surfaces | Flat battery casing with cladding | Accerlates air to reduce lift and turbulence. |

| Surface Details | Protruding handles and rain gutters | Flush handles and frameless glass | Maintains laminar flow along the vehicle sides. |

Intelligent Air Management

Adapting to the Atmosphere

The relationship between a vehicle and the air is not static; it changes constantly depending on speed, weather conditions, and cooling requirements. Consequently, the latest electric vehicles are designed to be "alive," with surfaces that physically adapt to the environment. This represents a move away from passive aerodynamics, where a shape is fixed, toward active systems that change the car's geometry in real-time.

One of the most common applications of this technology is the active air shutter system. While electric motors generate less heat than internal combustion engines, the battery and electronics still require thermal management. However, they don't need cooling all the time. Intelligent vents in the lower bumper remain tightly closed during highway cruising to force air around the car, reducing resistance. When the system detects a rise in temperature—perhaps during fast charging or spirited driving—these vanes automatically open to allow cooling airflow. This "breathing" mechanism ensures the car is only fighting the air when absolutely necessary.

Rear spoilers have also evolved. Instead of fixed wings that create permanent drag, many modern EVs feature deployable spoilers that sit flush with the bodywork at low speeds to maintain a clean look and reduce turbulence. As the vehicle accelerates to highway speeds, the spoiler extends or changes angle. This action disrupts the lift that naturally occurs over the curved roofline, keeping the rear tires firmly pressed against the pavement. In some advanced applications, these surfaces can even act as air brakes, increasing resistance momentarily to help slow the vehicle down, thereby reducing wear on the mechanical friction brakes.

Taming the Chaos at the Wheels

The wheel wells are notoriously difficult areas for aerodynamicists. A rotating wheel is an aerodynamic nightmare; it acts like a fan, churning air and creating a high-pressure zone that spills out the side of the car, disrupting the smooth flow along the flanks. Furthermore, the wheel well itself is a cavern that traps air, creating significant drag. In the quest for maximum range, addressing this turbulence has become a top priority.

To combat this, manufacturers are reimagining the wheel itself. The trend has moved toward "aero wheels" or covers that are largely closed off. By flattening the face of the wheel, the air can pass over it smoothly rather than getting caught in the spokes. While traditional car enthusiasts often prized open spoke designs to show off brake calipers, the efficiency gains from flat-faced wheels are too great to ignore in the electric era. These designs are often optimized to ensure that just enough air is drawn in to cool the brakes, but no more than necessary.

Beyond the wheel design, engineers employ "air curtains." These are small vents located on the corners of the front bumper. They take incoming air and channel it through a narrow duct, ejecting it at high speed across the outer face of the front wheels. This high-speed sheet of air acts as an invisible wall, sealing off the wheel well and preventing the turbulent air inside from spilling out. It effectively smooths out the side of the car using nothing but air itself. This intricate management of the wheel area contributes significantly to the silence of the cabin and the overall efficiency of the machine.

| Driving Scenario | System Behavior | Aerodynamic Goal |

|---|---|---|

| City Driving / Traffic | Air shutters open; Spoilers retracted; Suspension standard height. | Prioritizes cooling for components and maximum comfort over bump absorption. |

| Highway Cruising | Air shutters closed; Spoilers extended (low angle); Suspension lowers. | Minimizes frontal area and drag to maximize range and battery conservation. |

| High-Performance / Cornering | Shutters manage heat; Spoilers max angle; Independent active flaps. | Maximizes downforce for grip and tire traction; sacrifices some range for safety. |

Stability Meets Efficiency

Balancing Downforce and Range

The ultimate goal of these aerodynamic innovations extends beyond simply squeezing a few extra miles out of a battery charge. While efficiency is the headline metric, the stability provided by advanced airflow management is what transforms the driving experience. A vehicle shaped purely for low drag might resemble a teardrop, but without careful management of lift, such a shape could become unstable and "floaty" at high speeds. The mastery of EV aerodynamics lies in finding the sweet spot where the car cuts through the air cleanly while remaining firmly planted on the road.

Suspension systems are now frequently integrated into the aerodynamic equation. Many premium electric vehicles feature air suspension that automatically lowers the ride height as speed increases. By dropping the car closer to the ground, the amount of air entering the turbulent underbody area is reduced, effectively shrinking the car's frontal area. This lowers the center of gravity and improves the effectiveness of the flat floor and diffuser discussed earlier.

This integration creates a feeling of safety and solidity. In traditional tall vehicles or SUVs, crosswinds can be a terrifying variable, pushing the car out of its lane. However, by smoothing the airflow along the sides and managing the pressure differential around the vehicle, modern EVs are surprisingly resistant to these lateral forces. The air is guided around the vehicle in a controlled manner rather than buffeting against flat surfaces. The result is a drive that feels effortless and serene, where the driver feels less fatigue because the vehicle is not fighting the atmosphere, but rather working with it. The silence of the electric motor, combined with the lack of wind noise, creates a sensation of gliding that defines the next generation of automotive travel.

Q&A

-

What is Active Flow Manipulation and how does it benefit automotive design?

Active Flow Manipulation refers to the dynamic control of airflow around a vehicle to improve its aerodynamic efficiency. This technique can reduce drag and enhance fuel efficiency by adjusting the vehicle's shape or surface conditions in response to real-time conditions. In automotive design, it enables vehicles to achieve better performance and stability, especially at high speeds.

-

How is Drag Coefficient Tuning achieved in modern vehicles?

Drag Coefficient Tuning involves modifying the shape and surface features of a vehicle to minimize air resistance. This can be achieved through computational fluid dynamics simulations and wind tunnel testing, which help designers identify optimal shapes and features. Techniques such as active grille shutters and streamlined body panels are commonly used to fine-tune the drag coefficient for improved efficiency.

-

What role does Underbody Vortex Control play in vehicle aerodynamics?

Underbody Vortex Control aims to manage the vortices generated underneath a vehicle, which can contribute to drag and instability. By controlling these vortices, manufacturers can reduce turbulence, leading to a smoother airflow under the vehicle. This is often accomplished through the use of underbody panels or diffusers that streamline airflow and decrease drag.

-

How do Adaptive Rear Spoilers enhance a vehicle's performance?

Adaptive Rear Spoilers adjust their position based on the vehicle's speed and driving conditions to optimize aerodynamic performance. At high speeds, they can increase downforce to improve traction and stability, while at lower speeds, they can retract to reduce drag and enhance fuel efficiency. This adaptability contributes to both performance and efficiency across different driving scenarios.

-

What are the benefits of Wheel Well Airflow Optimization in cars?

Wheel Well Airflow Optimization focuses on managing the airflow around the wheel wells to reduce drag and improve fuel efficiency. Techniques such as wheel covers or deflectors can minimize the turbulence caused by rotating wheels, leading to a smoother overall airflow around the vehicle. This optimization can contribute to reduced noise, improved stability, and better overall aerodynamic performance.

-

Why is Crosswind Stability Enhancement important for vehicles?

Crosswind Stability Enhancement is crucial for maintaining vehicle control and safety in windy conditions. By designing vehicles to handle lateral wind forces effectively, manufacturers can improve stability and reduce the risk of accidents. This is often achieved through aerodynamic features like side skirts, spoilers, and active suspension systems that adjust to counteract the effects of crosswinds.